Equipment Supply

AMC Glass LTD (GTE Holding) and some Italian equipments manufacturing companies have signed exclusively commercial agreements to supply their equipment for glass factories.

Equipment supply:

●

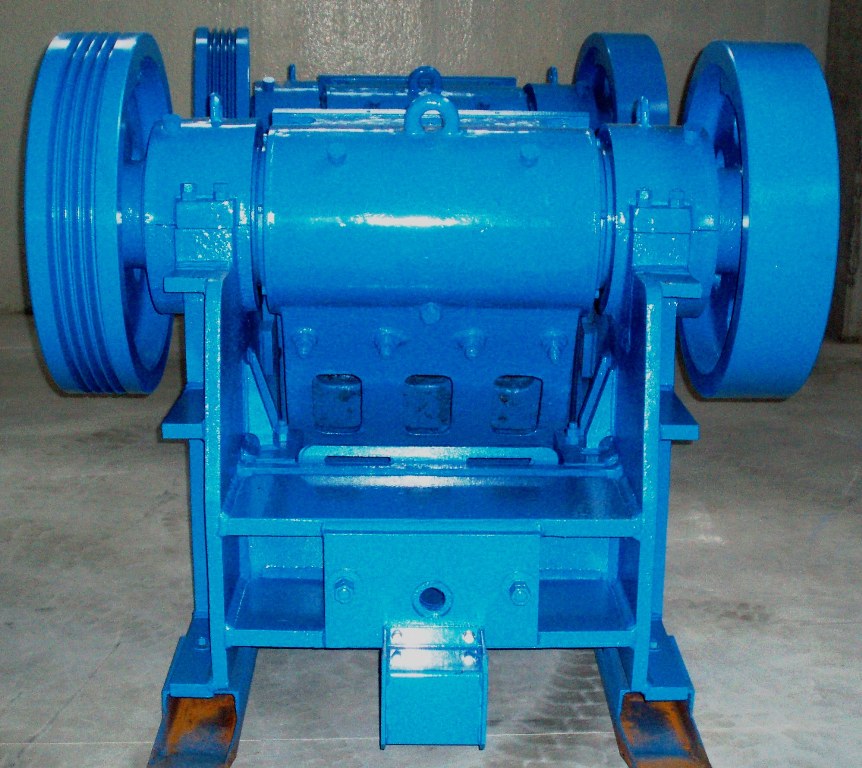

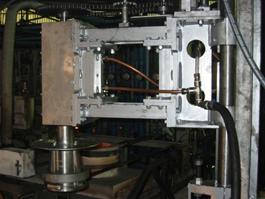

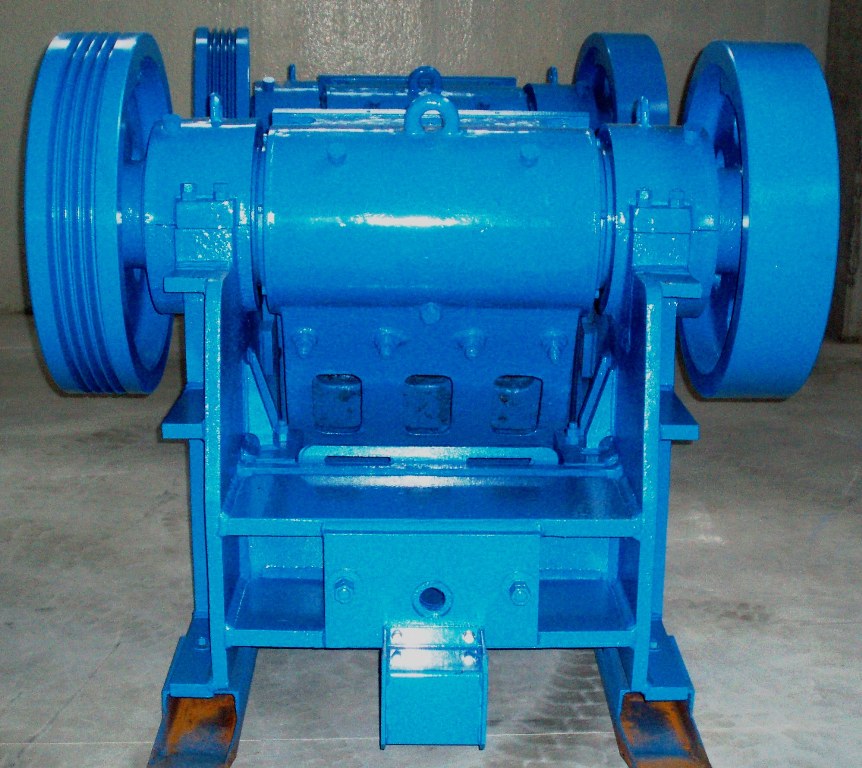

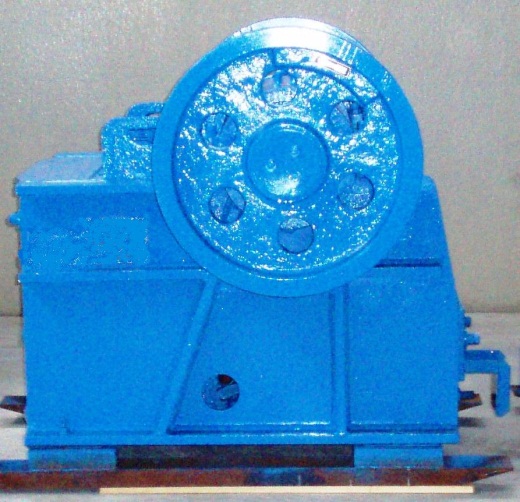

Jaw Crushers for raw materials and cullet

|

AMC Glass jaw crusher granulaors suitable for crushing material with any hardness features maintaining large productions and good shape.

- Heavy construction permits to work with very small close side settings

- Welded steel plate body

- Jaw holders os made of high tensile steel cast with 12-14% of manganese.

- Side walls are made of special CrNi steel

- Shaft forget, turned, treated and rectified, mounted on self aligning

|

●

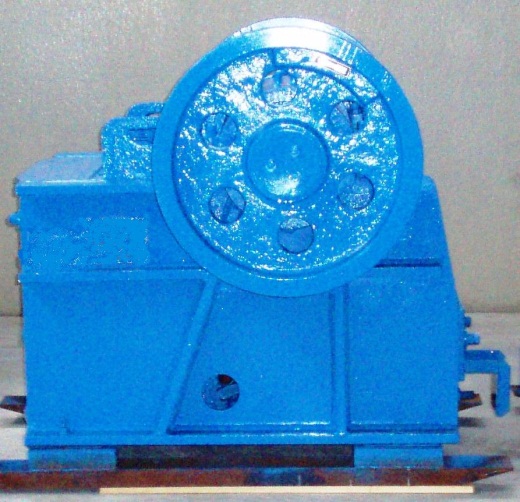

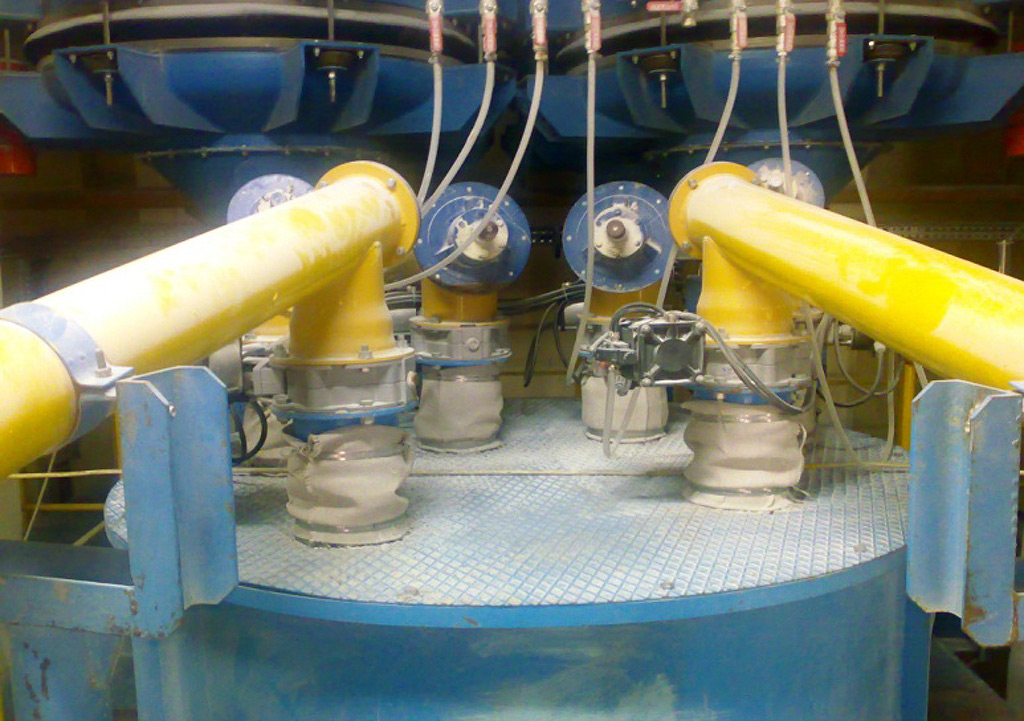

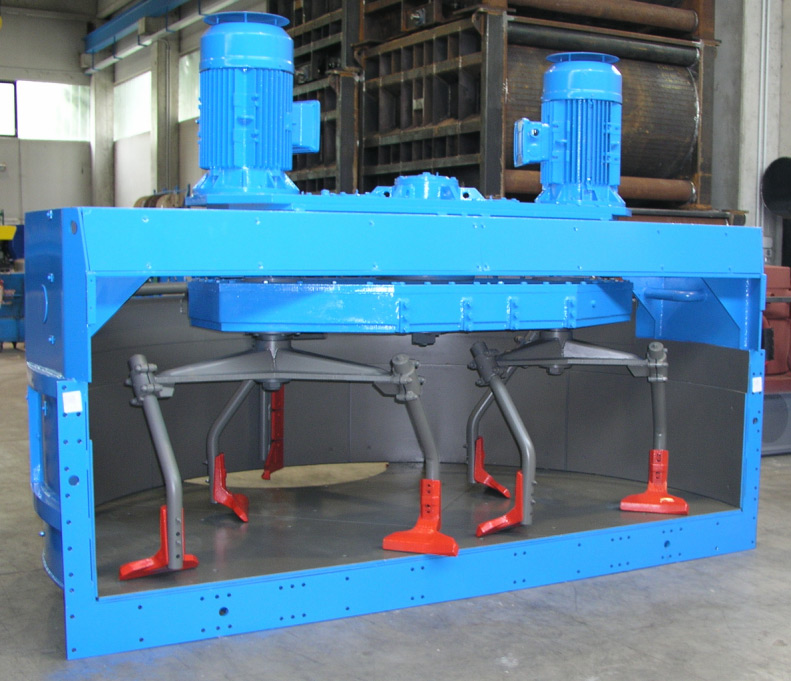

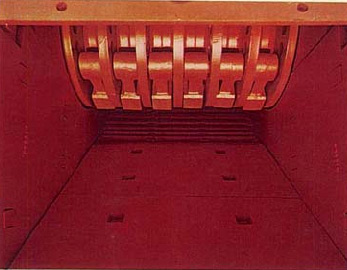

Hammer mill for raw materials and cullet

|

|

AMC Glass hammer mill are expressly designed for glass factory applications. These equipments has the best production efficiency with the lowest energy consumption cost. The fraction can be adjusted according to the production needs.

- Welded steel plate body.

- 12-14% Manganese cast steel hammers and side walls

|

●

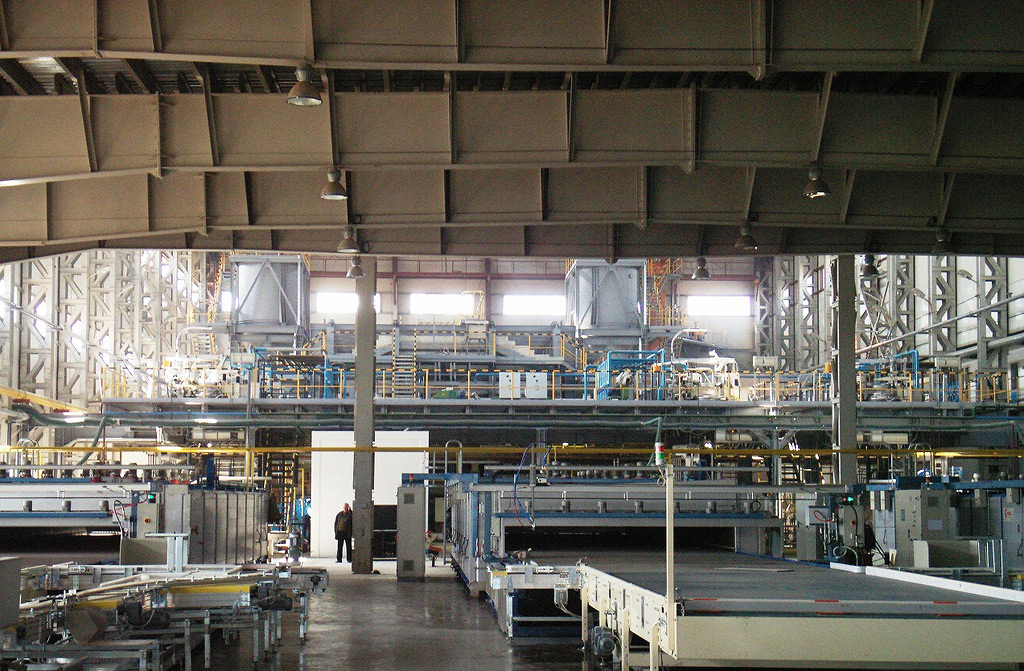

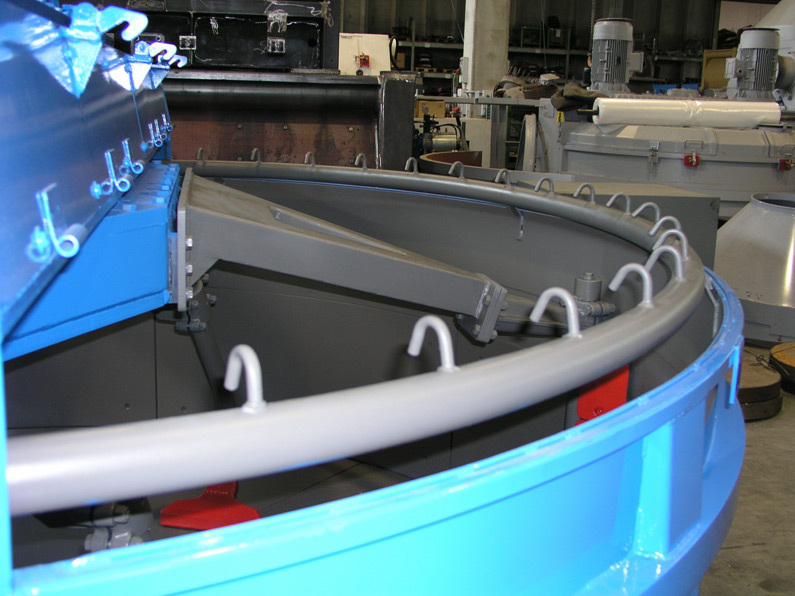

Batch main conveyor system

|

|

AMC Glass batch main conveyors solution foreseen dust proofing type completely closed to avoid the batch losses during the transport and assure to the batch operators safe working environment.

AMC Glass can propose a new batch conveyor modular system that optimizes sealing of any existing conveyor belt (any width, length, PVC, rubber, etc.), between the loading point and the unloading point. |

●

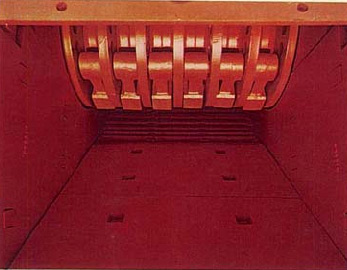

Annealing and Decorating Lehr

|

AMC Glass annealing and decorating lehrs are designed according to the highest technology and with high quality materials.

The lehr can be equipped with gas or electrical burners, high speed fans, thermocouples and thermo regulators produced by very well known worldwide companies. The belts can have different meshes types and sizes.

The lehrs are supplied "ready to run". |

|